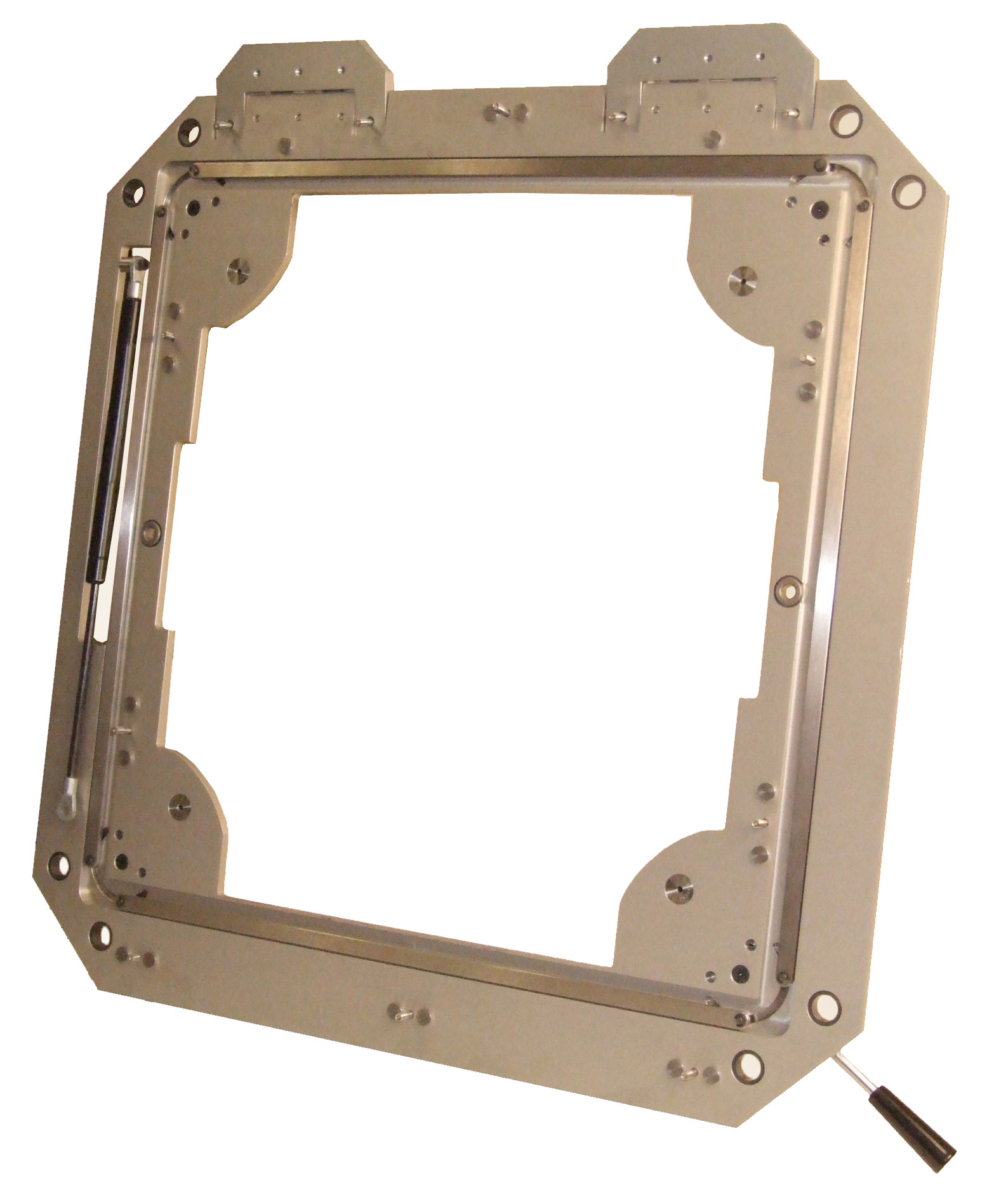

4-CAM

inTEST EMS 4-CAM docking systems have been an industry standard for more than 20 years. With an installed base of over 10,000 sets the reliability, repeatability, durability and ease of use of the inTEST EMS 4-CAM docking systems is well known. The robust linkage design makes the docking assembly virtually maintenance free for low cost of ownership.

With existing designs for 100’s of test systems, handlers and probers, the inTEST EMS 4-CAM docking system for your application is available today.

Key Features

Compatible Testers

The 4-CAM docking system can be used with all the most common test heads.

Linkage style test head docking

The Linkage Style test head docking replaces the traditional "Cable" style of connection with a robust direct linkage. The linkage design makes the docking assembly virtually maintenance-free for low cost of ownership.

All linkage docks are 100% backward compatible with existing inTEST EMS docking so that no changes are required to your existing handler or prober docking setups. And are compatible with inTEST EMS designed manipulator and test interface hardware for seamless MDI (Manipulator, Docking, Interface) integration.

Technical Specifications

Technical information below is for the “typical” 4-CAM linkage style docking assembly. With the myriad of tester and peripheral choices, inTEST EMS is committed to working with each customer to provide the optimal docking solution.

| Docking Pattern | Square guide pin pattern on 431mm (16.97") centers |

| Cam Diameter | 76mm (3") |

| Linkage Mechanism | Hard linkage |

| Coarse Alignment | Rectangular 560 mm (22.05") by 660 mm (25.974") pattern |

| Load Board Size | Easily accommodates load board size of 387 mm (15.25”) square including frame |

| Typical Operator Docking Force Required | 10 kg. (22 lbs.) to dock full test head (up to 272 kg./600 lbs. compression force) |

| Docking Mechanical Advantage Ratio | 27 to 1 |